Conveyor belt repair

The conveyor belt, like any complex movable mechanism, has a scheduled replacement period determined by the manufacturer. The service life of the belt and its individual parts may be shorter and lead to unscheduled repairs in case of violation of operational requirements.

Here are the most common signs that a belt is in need of repair or maintenance:

- Tape slip on main drum

- Severe wear on the belt surface

- Quick deterioration of auxiliary surfaces

- Tape break

- Break at the junction

- Belt edge deformation

- Longitudinal belt damage

- Rubber deformation

Violation of the rules for storing spare parts can lead to their failure before being installed on a working conveyor.

Failure to follow the rules of work on the conveyor has an extremely negative economic effect: it leads to downtime of the conveyor belt and an increase in the cost of its maintenance.

What are the causes of these disruptions?

- Tape slip on main drum. Cause of operation and maintenance violations: conveyor overload, belt shifting relative to the drum, slippage due to grease.

- Severe wear on the belt surface. Violation of maintenance leads to insufficient tension, as a result, deflection of the belt and slip.

- Rapid wear of auxiliary surfaces. Untimely maintenance and replacement of worn drums lead to the stopper of the upper branch twisting elements.

- Tape breakdown. Violation of the rules of operation leads to the fall of products from a height and the appearance of breakdowns on the belt.

- A break at the junction. The reason is the critical tension on the transport unit due to overload or blocking the movement of the drum by the product being moved.

- Belt edge deformation. Conveyor staff did not eliminate belt misalignment resulting in rubbing against the housing.

- Longitudinal belt damage. Working on worn rollers leads to belt contact with metal structural elements and failure of the belt.

- Deformation of the rubber layer. For the rubber surface, contact with oil- and liquid-based lubricants is critical. The consequence is the deformation of the rubber.

Everything you need to repair conveyor belts from a direct supplier!

+38 067 484 49 31

Ukrenergopostach ltd is engaged in professional repair of conveyor belts and lining of drive drums of conveyors throughout Ukraine. An accompanying line of professional activity is the supply of the necessary tools, components and devices for the repair and maintenance of conveyors.

You can buy from us:

- Adhesives, adhesives and solutions, including TP100 two-component cold vulcanizing adhesive;

- lining and sealing rubber for repairing conveyor belts and drum linings;

- Extruders-glue guns, grinding discs;

- conveyor belt cleaner knives (conveyor scrapers): ceramic and polyurethane.

Unforeseen factors, operation of belts in conveyors under high loads lead to their damage, technological wear. In such situations, according to regulatory requirements, the operation of the cargo conveyor is prohibited. The equipment must be stopped, then repaired, serviced. The performed procedures will help prevent an accident, avoid more complex damage to the conveyor device.

Types of conveyor belt repairs

In case of failure, it is impractical to change the tape completely. It is more efficient to carry out maintenance, to repair the damaged area. Restoration of normative properties is performed by the following types of reconstruction:

- by mechanical method;

- vulcanization;

- gluing.

In the first case, repairs are carried out with fasteners and tools.

Hot vulcanization is the most effective method. Requires the use of special equipment. The process is long and technologically complex.

Cold bonding is a popular way to quickly return a conveyor belt to its standard state. It takes 6 to 8 hours for the substance connecting the web to harden.

Docking the edges of the conveyor belt by hot vulcanization

- Special rubbers are used – lining, interlayer, as well as especially strong adhesives.

- You will need to use portable curing presses. Provides pressure on the edges of the canvas from 1 MPa at a temperature of +150 °C.

- You need to have rubber – interlayer, lining, as well as solvents based on ethycelate and gasoline. If the glue thickens ahead of time, it can be normalized with such a solvent. The surfaces of interlayer rubbers and the entire joint are smeared with glue.

- The cutting of the ends of the canvas should be stepped. If the conveyor fabric has a strength of up to 100 N / mm and reaches a width of not more than 1.2 m, then it is permissible to dock by a suitable mechanical method.

Peculiarities of repairing conveyor belts

In order for the reconstructed belt to be restored reliably and withstand heavy loads, it is necessary to carry out competent maintenance and repair work. This can only be achieved with the help of experienced professionals who comply with technological standards. You will also need special equipment, spare parts, tools. All this is possessed by specialized repair teams that perform work in almost any location of the facility.

- Coupling of TK type conveyor belts by cold vulcanization,

mechanical connectors, grooving, repair of conveyor belt covers, etc. - Coupling of TK and RTL type conveyor belts by hot vulcanization (if the Customer has a press vulcanizer).

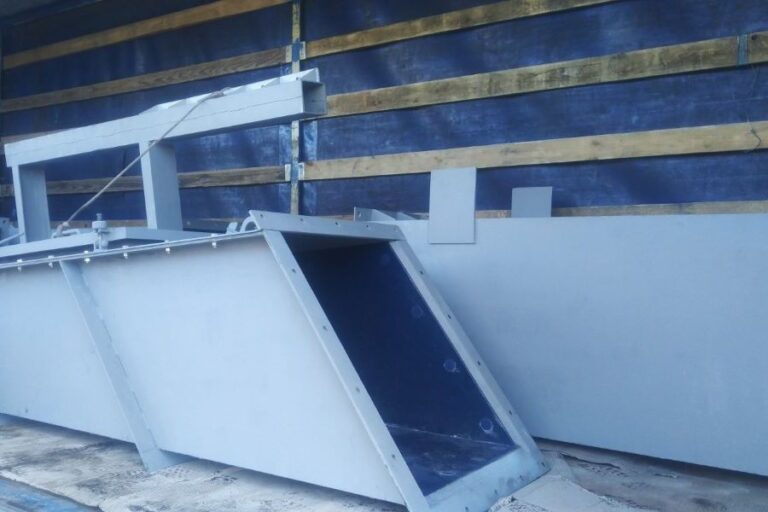

- The lining of belt conveyor drums (driven, tension, deflecting) and magnetic separators, if possible without dismantling the drum from the conveyor line, with special rubber profiled tech. plates of domestic and imported production, as well as rubber tech. Plates with ceramic-metal inserts.

It should be noted that in coal mines, 70% of fires in conveyor transport occur precisely because of slipping of drive drums in the belt. With a 1-year warranty for our work, the service life of the rubber coating is at least 3 years, subject to the rules for operating belt conveyors.

- Rubber coating or spraying with polymeric materials of metal surfaces of pipes, bins, etc. to prevent sticking of the load and wear of the walls of the equipment. Spraying with special anti-adhesive compounds was carried out for Tis Coal LLC, Tis Ruda LLC.

- Supply of drum cleaner blades and secondary cleaning scrapers of a conveyor belt with replaceable polyurethane segments and a torsion clamping device. The use of replaceable polyurethane cleaning elements eliminates the formation of an abrasive core between the belt and the cleaning element compared to a traditional rubber scraper and, as a result, the service life of the conveyor belt is significantly increased.

- Supply of tools (including press-vulcanizers for any belt width) and consumables for joining conveyor belts and lining conveyor drums manufactured by SHANXI HUAO INDUSTRY AND TRADE GROUP CO., LTD., as well as other brands (i.e. Tip Top, Nilos, Matador).

- We conduct master classes on joining conveyor belts, lining drums for the Customer’s personnel.

Send us your request. Our specialists will promptly answer any questions about the terms and conditions of delivery or work.